Ⅰ Consulting Service

Consulting - Electornic material consulting

Electoric material business is likely to be long-run deal in general. However, you must show the best performance in cost, production quality and speed compared to your competitors to be nominated as a partner. Hence, development strategy is very crucial in this field. KMT’s support based on strategic marketing theory would be helpful for you to make a decision on which market to focus, and also helpful to develop high quality production in short term.

Corresponding to such needs.

| “Want to expand an electronic material business.” | Long-established electronic material manufacturers | |

|---|---|---|

|

|

Business model development

●Providing one-stop-support; from research and market selection to strategy construction.

●Business model proposal with future market trend analysis.

●Business model proposal based on re-organization of your company’s competences.

There are many small companies who have advantages in technology but not in sales & marketing. We support them creating “cash cow” business by finding small-but-growing market and concentrating all the resources to acquire large share in the market. In that way, small companies can contribute to the extension of small market and enlarge the business scale of itself at the same time. We help them finding high potential small market, and support them constructing marketing strategy to distinguish themselves from competitors.

Development strategy proposal

●Supporting to clarify the purpose and positioning of the development in whole business activity.

●Supporting the optimal goal setting and in-house presentation.

●Advices on the optimal resource allocation and the creation of mission statement.

●Ongoing support of production site management is also available.

“Development strategy” is the most important part of business construction. We start with preparation of in-house document to make all workers being conscious to the background and the goal. And then optimal resource allocation between the existing work and new development work would be calculated. finally, the most adequate management method and organizational structure would be proposed.

Market trend research

●Too complicated to understand? We offer keys to read the electronic material market.

●KMT’s rich information source is definitely helpful in your business.

●Searching for another business chance? We propose you the near-future business model.

The growing market of electronic material changes very rapidly, and also it extends to various fields. For instance, touch panel had been shifting its model from “resistance film model”, via “electro capacitance model”, to “in-sell model.” When market changes, main-players of the market also likely to change in history. Therefore, it is very important to watch the market trend and forecast what comes next to update your business portfolio. KMT’s business consulting is helpful to read the market trend and to update your business model.

Consulting - PCB

Customer’s requirement on QCD (Quality, Cost, and Delivery) is always high in PCB industry. Cost performance, yield rate, and delivery speed are all related so that if you have succeeded in improving production quality, then it will contribute to cost-cut as well. By improving overall equipment effectiveness, QCD will raise high dramatically. Therefore, QCD improvement effort is very effective way to enlarge profit with no large investment on equipment. KMT’s support is very helpful to develop high density product with required QCD, and to produce a mass production.

Corresponding to such needs.

| “Need to cut production cost.” | “Want to improve quality control and production capacity.” | |

|---|---|---|

|

|

Manufacturing quality improvement

●Having rich know-how on yield rate improvement and production quality control.

●Supporting yield rate improvement of smart phone board.

●Supporting technical coaching for manufacturing site staffs.

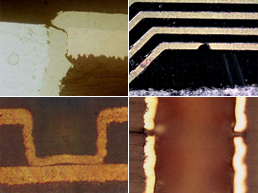

Based on our research, an average yield rate of smart phone board is around 92% in average, and the remaining 8% is discarded. However, the yield rate can be improved dramatically. In fact, 60% of “defectives” happens in circuit step or laminating process, so we count the number of defectives at these processes, check the quality of lines and of work-flow, and then conduct manufacturing site workers the better operation to improve yield rate.

Overall equipment effectiveness improvement

●Having special know-how in improvement of overall equipment effectiveness.

●Reducing defectives by quality improvement.

●Effective work-flow improvement based on our advanced work analysis.

In high density wiring board manufacturing, an average rate of overall equipment effectiveness is around 65% based on our research. Therefore, about 35% is counted as “loss” which is to be improved. While “stop-loss” and “performance-loss” need to be improved by productive effort, “quality-loss”, 40% of total loss, need to be improved by quality improvement effort. Starting with classifying “failure products” and “re-work products,” KMT would support you to raise the quality of each classifications and leads to the betterment of overall equipment effectiveness.

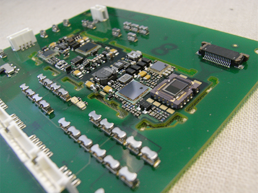

Product development and process building

●Total support on PCB product development.

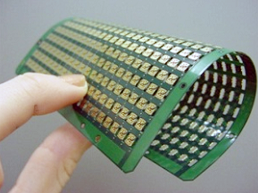

●Rich know-how in high density and embedded work.

●Support from KMT’s reliable network source will be helpful as well.

It is effective way of adding values to your business by releasing advanced product to the market. KMT’s international PCB specialist’s network would be helpful to solve any kind of problem in PCB development. Especially, we have strength in the development of very high density products and the embedded works.

Consulting - Component mounting

In component mounting business, required yield rate from client is always 100%. At the same time, a product trend is heading toward compactness, levity, and high functionality, and you must respond to difficult technological issues such as high density mounting on thin base. Our special know-how on “mounting design”, “line conditioning”, and “optimization of working environment & condition” would be definitely helpful for improving production and fulfilling your client’s requirement.

Corresponding to such needs.

| “Need to improve quality of surface mounting.” | “Want to standardize the mounting design.” | |

|---|---|---|

|

|

Manufacturing quality improvement

●Pin-point coaching for quality improvement.

●Having rich know-how in mounting design and manufacturing process construction.

●Semiconductor packaging is also available.

The wide range of know-how and the techniques are crucially required to the quality improvement of component mounting. Especially, know-how in mounting design, knowledge in component & board surface, and solder printing skill are very much required. We support your mounting business with specialty knowledge, including semiconductor mounting knowhow.

Productivity improvement

●Increase the productivity of complicated mounting.

●Proposing optimal setup for each lines.

●Keywords are “automation” and “inspection technology”

The yield rate in mounting business is based on productivity level. However, mounting technology is getting more and more complicated and difficult, so that it is crucial to setup the stable and balanced operation line to maximize the productivity. It is very important to operate each lines non-stop in balance with other lines. Our proposal is based on our knowhow in “automation” and “inspection technology.” Please contact us for more information.

Ⅱ Diagnostic service

Diagnosis - Manufacturing process diagnostic (PCB)

Corresponding to such needs.

| “Want to know what is happening in product line process at work site.” | “Want to recheck the correctness of our improvement effort in the eyes of third parties” | |

|---|---|---|

|

|

How are the quality in each line process?

●Pointing out the in-process problems by technical point of view.

●Full line diagnostic or model line check.

●Submitting “in-process quality check report”

Through in-process check, we sort out the problems by analysis of examined data in each process and worksite audit. There are two types of diagnostics, one is “full line diagnostic” and the other is “model line check” which is conducted based on QC process sheet.

【Report】

In-process quality diagnostic report・Defect classification and cause process list (optional)

Rework process check

●Visualize the hidden re-work process to improve productivity.

●Find out the problems with list check, and then worksite confirmation.

●Submitting each line’s process check report.

In many cases, rework, a hidden impediment to productivity, is not seen as major problem because of its difficulty in data reflection. However, productivity will certainly improve by checking and revising the rework process. After detailed process check, we sort out the problem through field check. Our diagnostics covers individual model check as well as full-line diagnostic.

【Output document】 “Rework process check report”

Diagnosis - Business Model Diagnosis

Accompanied with amazing advancement of IT, customer’s requirement for compactness, levity, and high density also rose high. Furthermore, competition of technical capabilities and cost performance is heating up. The market is changing so fast that today’s prosperity does not count for tomorrow’s success. It is very important to watch ongoing trend and predict the future of the market. Our support includes diagnosis of business model from future trend perspective.

Corresponding to such needs.

| “Need to brush up the existing business model with specialist’s advice!” | “Need business model check before market entry!” | |

|---|---|---|

|

|

Electronic material model diagnosis

●To realize the No.1 quality with low cost!

●Making advises based on the definition of strength & weakness in your business comparing to the industry standard.

●Business plan diagnosis based on future trend analysis.

Product lineup and its quality is key factors for making good deal in electronic material business. For acquiring your original position in the market, it would be helpful to define your strength and weakness in comparison with the industry standard so that you can select the best product lineup and set the optimal goal for its quality. Now we are watching the market trends of photovoltaic, smart-grid, eco-car(HEV, EV, PHEV), light emitting diode(LED), and display. KMT would inform you with significant changes in the market and strongly support your business.

PWB business model diagnosis

●Business model diagnosis by specialist of PCB and Semiconductor PKG.

●Timely advise based on marketing point-of-view

●Inform you with growing need of customers.

With expanding use of PCB and semiconductor PKG, customer’s request is getting higher year by year. It is very crucial for your business plan to watch ongoing changes of market needs, such as an acceleration of outdoor-use according to the spread of smart-grid, push up production of power board and control board according to eco-car increase, rising wire density corresponding to higher resolution image, and so on. KMT would check your business model from specialist point of view, and support your business with the best advises.